Scanclimber hoists played an important role in building the giant luxury cruiseliner, Mein Schiff 5, at Meyer shipyard in Turku. Meyer Turku is one of the leading shipyards in Europe, and part of German-based Meyer Werft. Meyer Turku specializes in building cruise ships and other passenger vessels. It has a long history in shipbuilding, dating back to 1737, when the yard in Turku started. Mayer Werf has built more than 1300 vessels over the years.

Mein Schiff 5 construction challenges

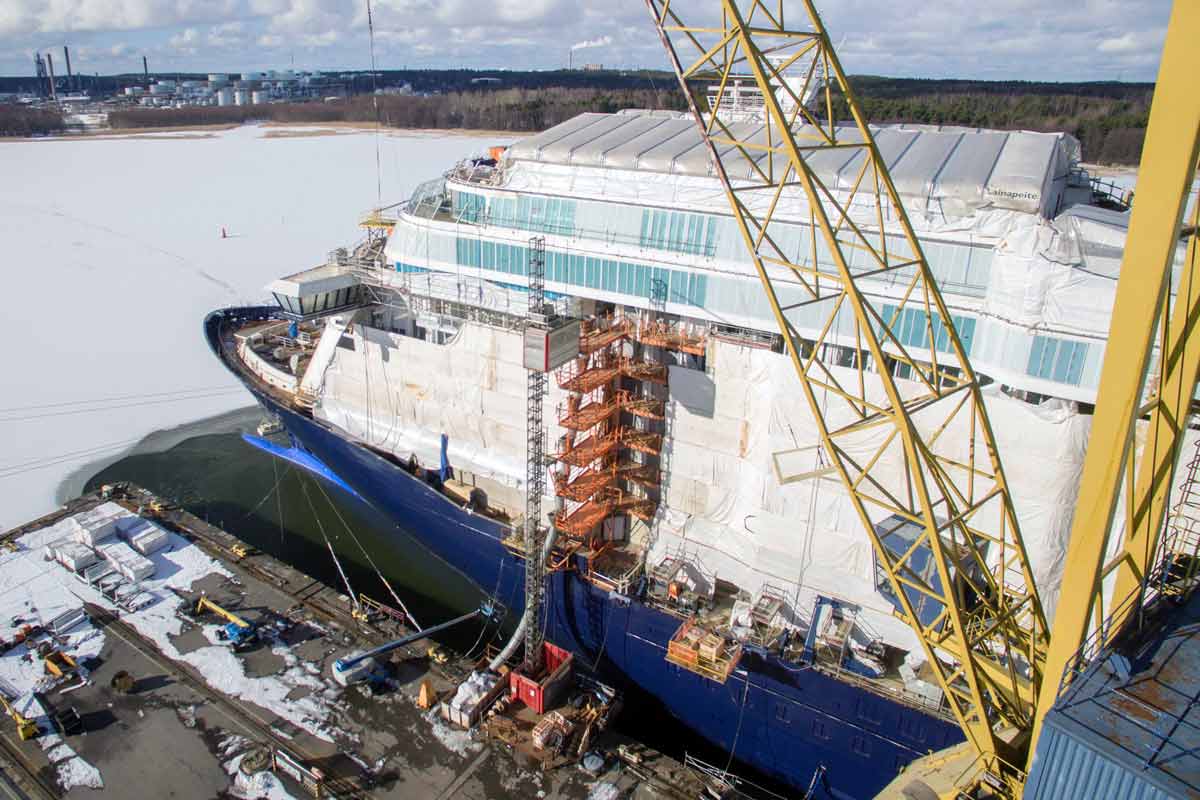

The construction of Mein Schiff 5 started in November, 2014 and was completed on June 21th, 2016. Mein Schiff 5 is a huge luxury passenger liner: 295 meters long, almost 36 meters wide and has 15 decks. With its 28,000 kW diesel engines, Mein Schiff 5 can cruise at 21.7 knots. There are 1267 passenger cabins, 13 restaurants and the same number of bars and lounges. Mein Schiff 5 made it’s maiden voyage on June 26th, 2016. 11 days ahead of schedule.

During the construction time a lot of material and personnel had to be transported up to the vessel’s 15 decks for inside finishing work. A crane could do some of the work but it was slow and could not transport personnel vertically. The challenge in this case was to deploy vertical transportation outside the ship, so that it would not interfer with the tower crane movement alongside the vessel.

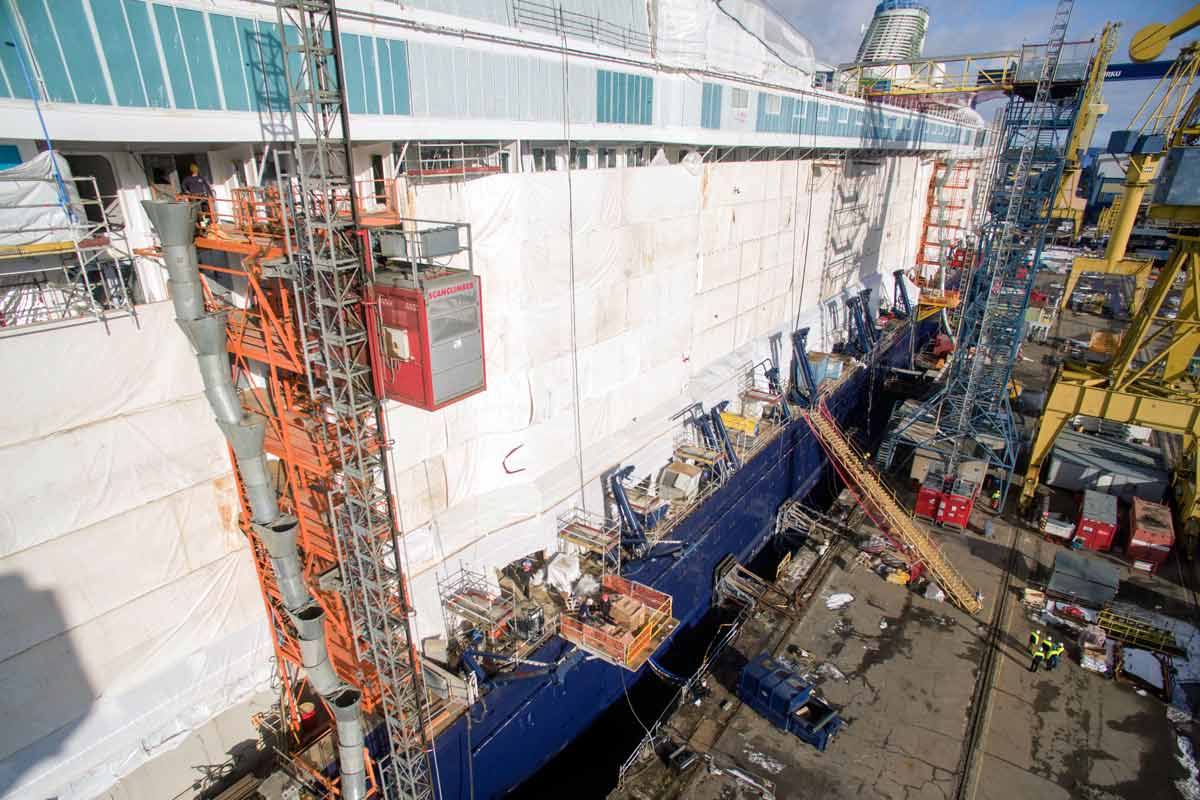

Finally the viable alternatives that the rental company, Cramo, offered to Mayer Turku were reduced to one: Scanclimber Wega construction hoists.

The construction hoists occupied very limited space on the site and provided an efficient way to transport material and personnel to and from the vessel. The landing levels for hoists were deployed in such a way that material transportation was possible to all 15 decks of the ship.

Scanclimber machines used at Meyer

Altogether, 4 Wega hoists were used; one twin cage SC2032F and two single cage SC1837 in the following manner:

- A twin SC2032F-65 hoist was installed to carry material and personnel to the center of the top deck.

- One single SC1837-65 was deployed at the bow end of the vessel.

- Another single SC1837-65 was deployed to cover the stern end of the vessel.

Special features of the hoist ground stations

The ground station for the SC1837 hoist differed from the standard version. The hoist was bolted on to a strong wooden foundation half a meter above ground level. Additionally, the hoist was equipped with both a front door and an additional wider door on the side. This enabled optimal use of the hoist. More material could transported to the vessel and back because the hoist was accessible from two sides.

The twin SC2032F hoist was mounted on a normal concrete ground foundation. The other single hoist SC1837-65 was also mounted on a ground station and was equipped with a front door and an additional back door.

Landing Stations

The landing stations for both single SC1837’s were on 6 levels, each covering all 15 decks, whereas the twin SC2032-65 hoist had only one landing station on top of the vessel.

Benefits of using several hoists

The Mein Schiff 5 was delivered 11 days ahead of schedule. Using several hoists in a versatile configuration was one factor contributing to the timely completion of the vessel. Additionally, the configuration of the hoists increased efficiency and work quality. Having separate hoists, both at the front and rear, made balanced distribution of materials to the decks possible. The twin hoist helped to achieve fast access with a high payload capacity to the top of the ship.

Easy access to front, center and rear parts of the ship improved the rate of work done per hour and accelerated the performance of the whole ship building project.

| Project Facts | |

|---|---|

| No. of Hoists used | 4 |

| Hoist Models |

|

| Height achieved |

|

| Project start | 18 Nov, 2014 |

| Project Completion | 14 July, 2016 |

| Special features |

|

RU

RU  PL

PL  FR

FR  DE

DE  EN

EN