Roche Tower is a skyscraper recently constructed in Basel, Switzerland. The building, after completion will be the headquarters of the pharmaceutical company Hoffmann-La Roche, which is scheduled to be opened in second half of 2015. With the height of 178 meters, Roche tower becomes the highest-ever high-rise tower over Switzerland and second tallest building in Switzerland with state of the art architecture with white facade presenting glimmering view of the building, seen miles from the beautiful city of Basel.

The challenges

The negotiations based on the requirements of technical solutions for the tower initiated with Scanclimber® in the month of July, 2012. There were certain complexities in the Roche project in terms of construction aspects because of its distinctive design. Scanclimber® needed to propose a technical resolution with their product that could effectively address below mentioned issues,

- Quick transportation of several passengers at a time

- All floors not vertically aligned

- Closure of facade before hoist disassembly

The solutions

Quick transportation of several passengers: The high scale of construction project like Roche tower involved a lot of passengers to use hoists not only during intervals like start-up, lunch or finishing hours but also during the entire working hours. At such sites, there are liftmen operating individual hoists but with random calls for the hoist from any location including cage itself causes it to stop to the nearest call point. This interrupts the work process, which is certainly an economical drawback. Scanclimber®, having special control system, provided the solution efficiently where the memory device in the system stores the calls. Calls were saved in the memory and shown in the cage to the operator. The operator or driver of the cage addressed them according to capacity and priority which helped the flow of work systematically and did not interrupt the order of calls to hoist.

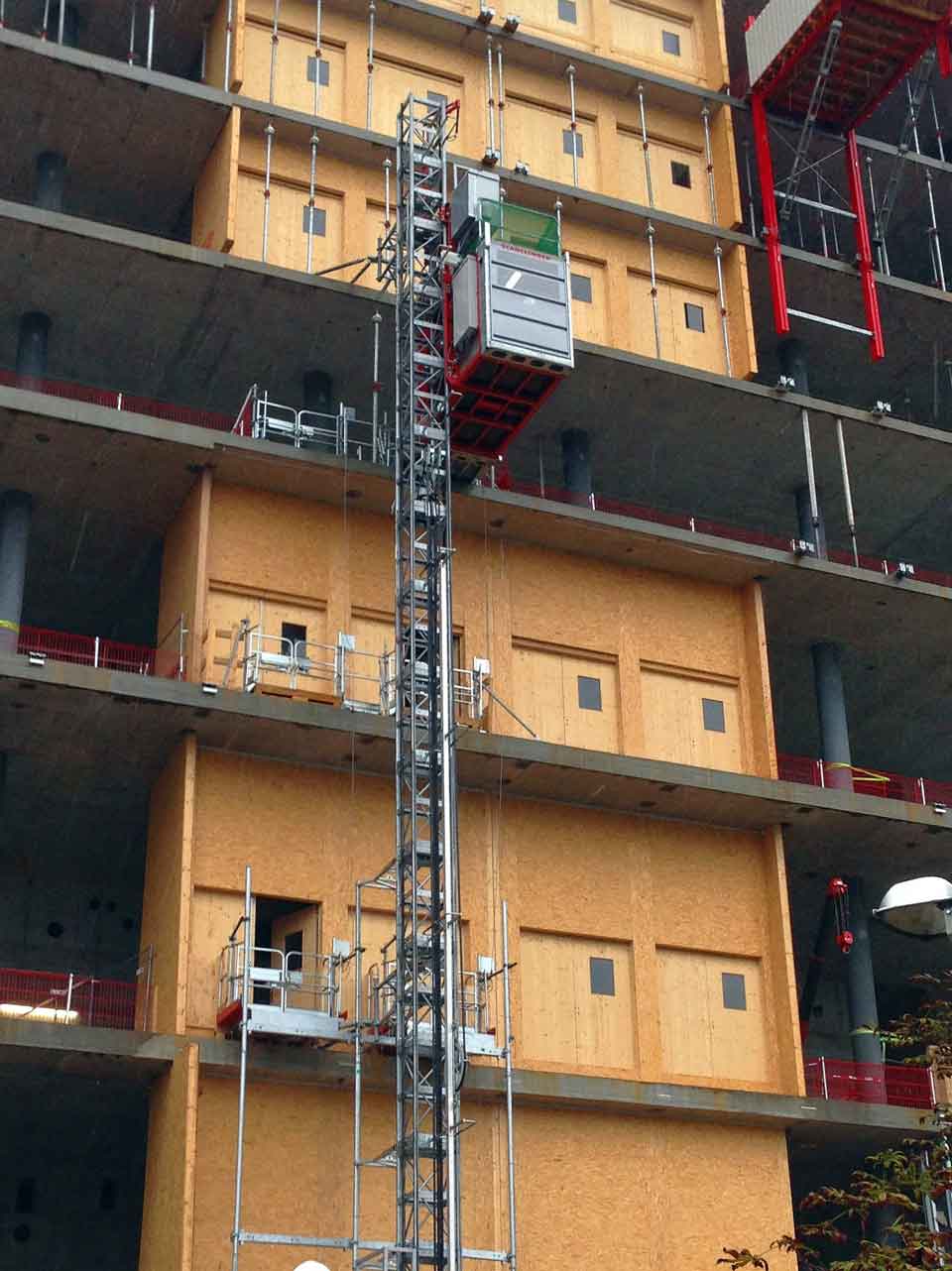

All floors not being in vertical line and closure of facade before disassembling of hoists: The unique architectural design of Roche Tower Building caused the construction to be carried out in a way that floors of the building were not consistently in vertical line. In order to deal with this technical hitch, hydraulic ramp was used in order to access the floors. Another requirement was that the facade was needed to be closed before the disassembly of hoists is performed for which special anchoring system was employed having opening for only anchoring pipes from the facade and rest being closed.

Utilizing Scanclimber's most powerful hoist

The proposed product addressing the solutions for Roche tower was to utilize ‘two twin cages, SC3232 where one can go high as 100 meters and other 176 meters. SC3232 is the most powerful manufacture hoists in the Scanclimber® H65H construction hoists product family possessing loading capacity of 3200 kg or 24 persons with maximum reachable anchored mast height as 300 meters. The hoists at Roche tower were used for both transportation of material and personnel. A unique aspect provided with this solution was the fact that hoist was not attached to a concrete base but had their self-sustaining frames. This characteristic resulted in reduced founding costs for hoists along with the advantage of faster installation.

Special features

In addition to addressing the certain intricacies in the project, Scanclimber® SC3232 contained extra features including special landing system where main station for passengers was established 5 meters above ground level to make way for trucks to come in at the site and load the material inside the cage. Fire fighter control was available where a switch key could allow fire fighter to control hoist from ground station. In order to have service, reaction time was 2 hours with availability of electric subcontractor on the site. Emergency call system was another feature where the cage could directly be controlled from Roche central control in case of any crisis. < p>From the beginning of negotiations to finishing stages of the product in production usage, it took only 1 year proving the quicker results according to customer requirements, efficient logistics, quick installation, proficient utilization and faster disassembling of the product. Scanclimber® was chosen because of its high quality product with flexibility and reasonable price. These products could be used under different circumstances and various building structures. Stable masts, unique control systems and special anchoring procedures were used in this construction providing competent solutions to the technical problems in the project.

| Project Facts | |||

|---|---|---|---|

| Height of Roche Tower | 178 m | ||

| Hoist used | SC3232 | ||

| No. of Hoist Used | 2 | ||

| Reachable Height of Hoist | 100 m ; 176 m | ||

| Max. Loading Capacity | 3200 kg or 24 persons | ||

| Negotations Started | July, 2012 | ||

| End of Production Usage | July, 2013 | ||

| Special Features |

|

||

RU

RU  PL

PL  FR

FR  DE

DE  EN

EN