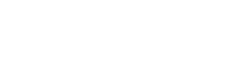

Opposite the Luxembourg railway station, the ‘Centre Postal Gare’ construction work is progressing at full speed. The building of the new official headquarters of the Luxembourg Post is on track for completion in 2022. The facade work started at the beginning of 2021 on the 27,700m2 complex.

Demanding installation in Luxembourg

Under the monument, the facade will be integrated into the new building. Some other notable features are also planned for the facade. These special facade features originate from the ‘Platinum’ certification by the German Sustainable Building Council (DGNB). The certificate demands compliance with strict environmental and sustainability criteria.

Challenges

The new facade is attached to a wooden support structure, and it has a construction depth of 900mm. Natural stone facade swords are integrated in some areas, arranged in a grid of 650mm. With a deadweight of around 200kg per centerboard, the story-high parts are cantilevered by about 600mm.

Temporary storage space and the working area are very confined. The on-site cranes are in heavy use. The installation took place during the shell construction when only 3 of 9 floors were completed. The facade’s depth was challenging, the schedule was tight and the anchoring possibilities were limited.

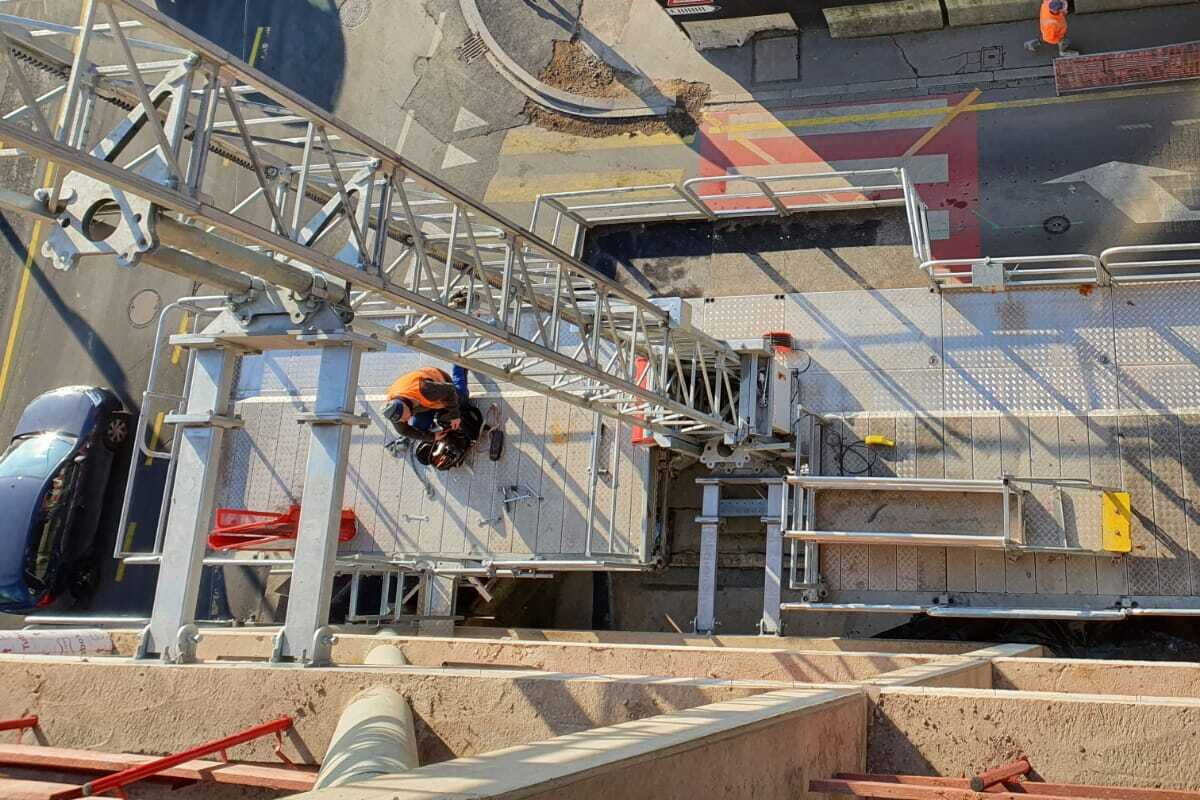

The first requirement for the facade access was to install lower facades while the building shell was being built on the floors above. The second requirement was to distance the workspace 900mm further out at the bottom than at the top of the building and arrange the distance change dynamically.

The workers needed temporary storage space daily for the facade profiles and swords on each working floor. Each installation team needed to use the lifting device independently. Material and elements need to be transported from the ground to the operating level without the on-site crane.

Solution

The company responsible for the project was Annen plus S.A. from Manternach, Germany. The company started in timber construction and is now breaking into new segments of the business. Now, they also transform wood, glass, and metal into intelligent and aesthetic facades.

It can be a demanding task using wood for constructing complex facades. It requires planning, construction knowledge and, as was also evident in Luxemburg, post assembly planning.

Because of the project complexities, Annen had to think carefully about a vertical transportation solution to solve the site’s logistic challenges. After evaluating different possibilities, the answer was a combination of mast climbing work platforms, trolley rails, adjustable distancing from the facade, and some project-specific components. The final decision was to take the Scanclimber’s vertical access concept with SC8000 mast climbers.

The Scanclimber SC8000 vertical access concept

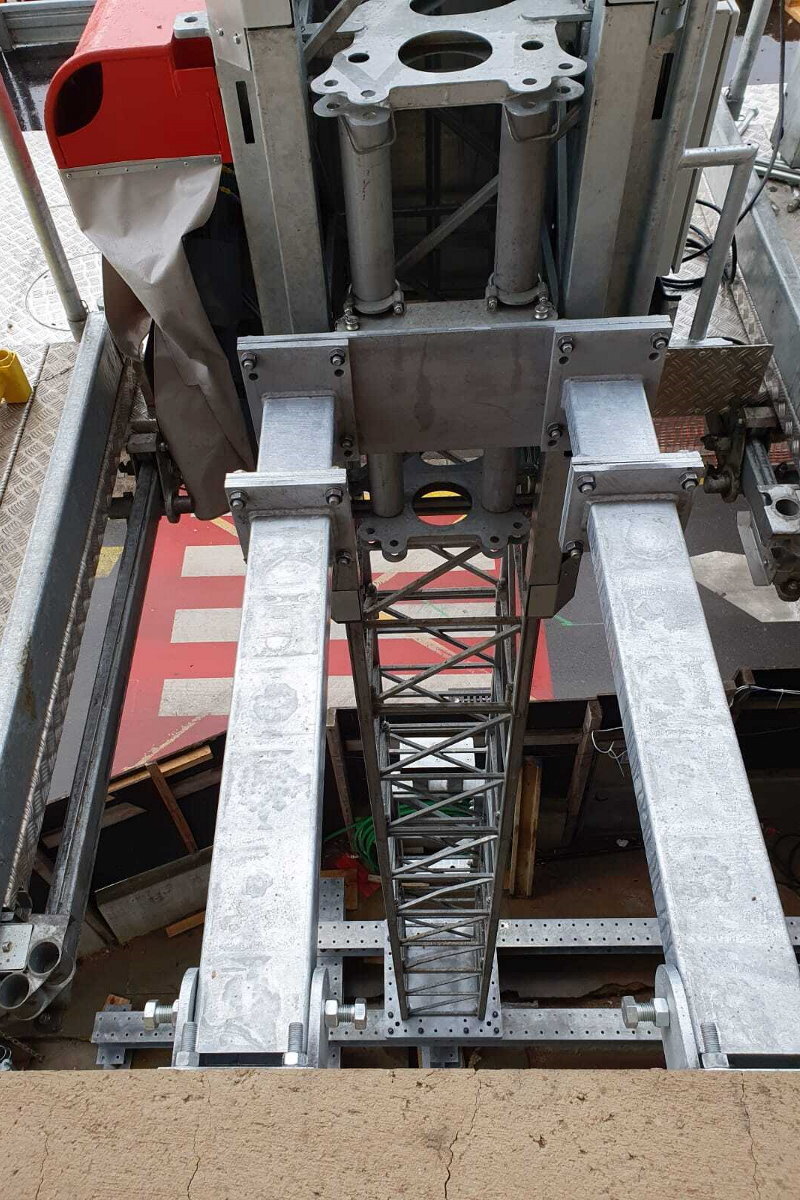

In the project, Annen is using several 12.1-meter long SC8000 platforms. The load capacity of the single-mast climber is 3,500kg, mainly because of additional components and options attached to it. The remaining payload of 1,550kg met the needs of the assembly teams.

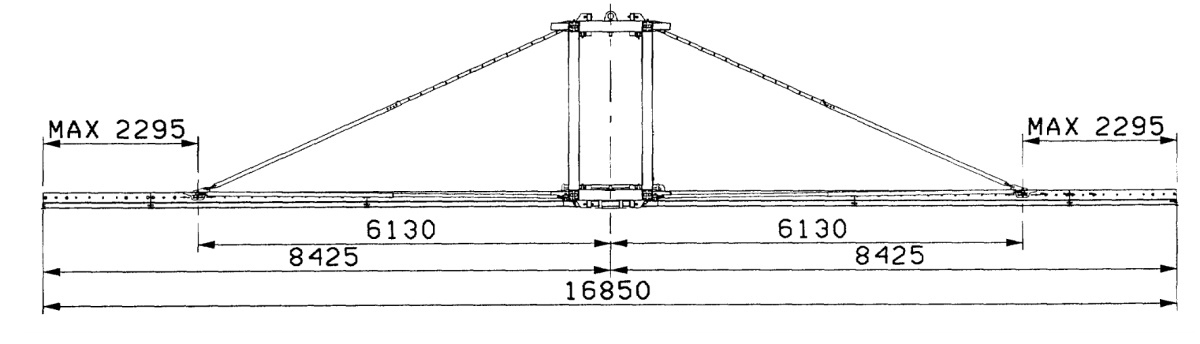

Users can extend the platform width independently on each side of the platform. In this project, an extension of around 900mm was sufficient. The electrically driven deck moves in and out fast and flexibly. The distance can be adjusted just by pressing a button. Because of the adjustable deck, it is easy to go past any protruding parts.

Platform with retracted extended deck.

Platform with partially extended deck.

Due to the limited space, the contractor constructed the foundation with a flexible support structure. Because mast climbers were above pedestrian tunnels, it was necessary to restrict access to the roadway. The access restriction was ensured electrically by using lane-limiting switches. Higher buffers were installed on the mast for protection in the event of an emergency. Even in the event of a lowering in a power failure situation, a ‘collision’ will not happen.

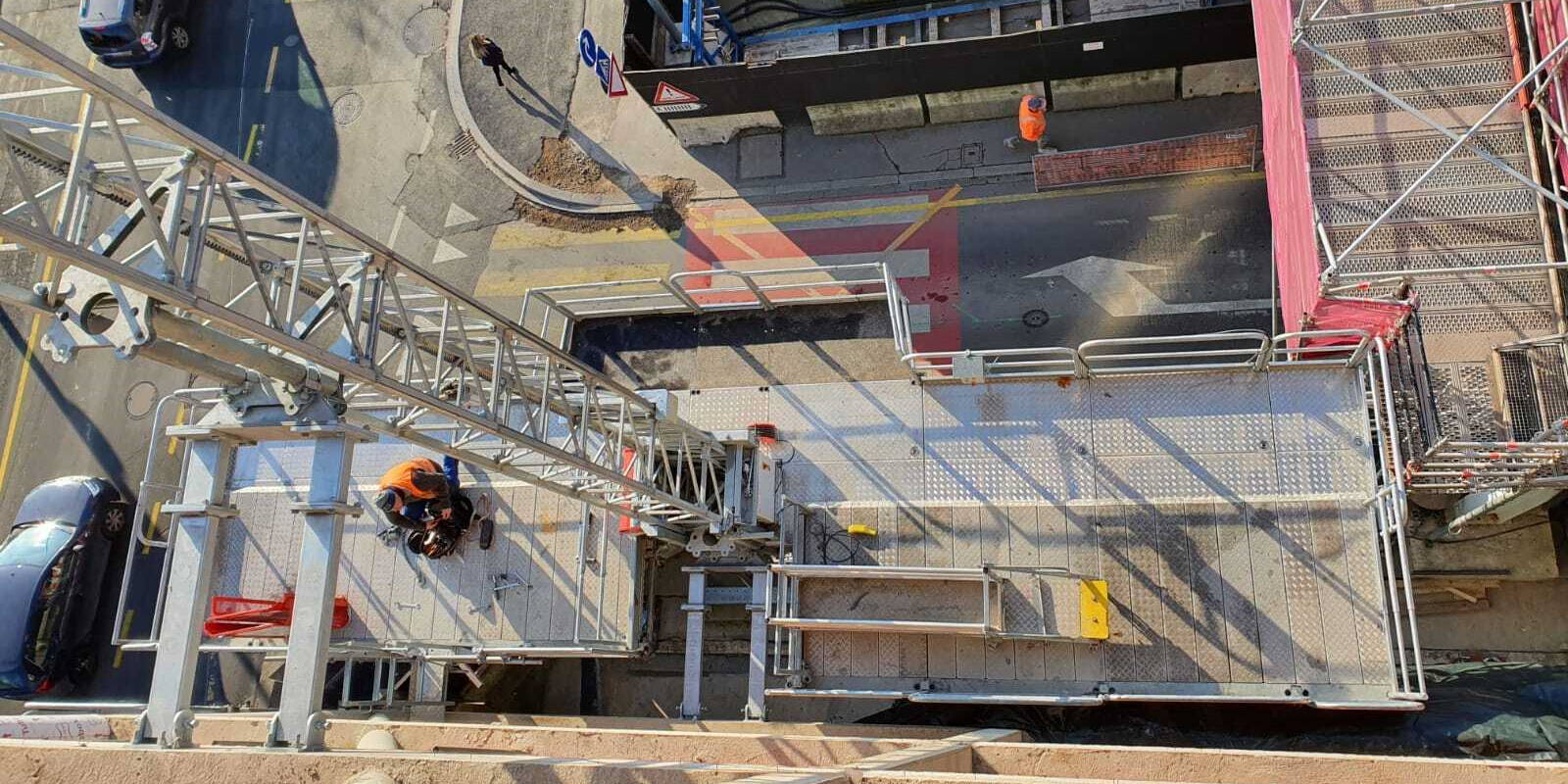

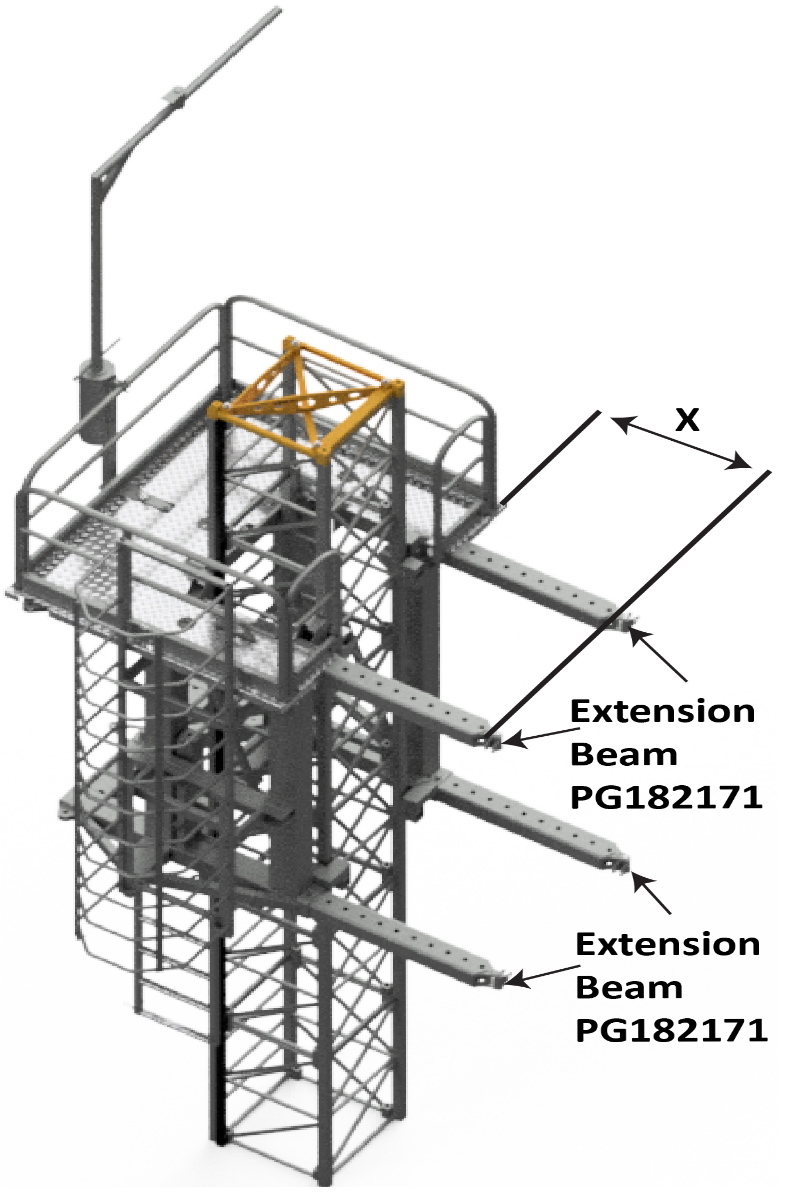

The glide rail serves as the lifting device for face elements. It is fixed to a frame on the mast. If needed, it can be lifted into a higher position by crane or the platform and then locked to a mast position. The glide rail load capacity depends on the length of the arm. The glide rail system’s lifting ability is 600kg on a 16.90m long single mast platform. For shorter versions, the capacity goes up to 1,000kg.

In the Luxemburg Post Office project, the builders use electric hoists manufactured by Tractel® with 500kg capacity. The radio-controlled hoists are used to lift material from the ground to the platform. Then the glide rail crane can reach above the platform and pick up the material on the front side. It is also possible to add lifting space by retracting the extension. The builders also use the hoist to pick up the parts from the platform and position them on the building for installation.

The rail position is variably adjustable. X = max. 100mm, to ensure a precise positioning of the gliding rail.

Scanclimber customized the mast’s anchoring for this project since the maximum width should not exceed the distance between the swords on the facade. The contractor used precast concrete Halfen rails for fastening the anchors to avoid unnecessary drilling.

Designers needed to adapt the platform’s access because of the higher-than-normal parking position of the mast climber.

Since the pedestrian tunnels on the ground level prevent the platform from reaching the ground level and the ramps, a transfer ramp was installed. This TUV approved ramp, generally used for access between two platforms, gave access to the first floor. The ramp’s width was only 600mm so that builders could use the ramp later between installed swords.

Conclusion

Scanclimber has a formidable track record in providing vertical access solutions to various projects in Central Europe. This project is another proof of concept for the fact that demand-oriented access solutions can help to considerably improve the construction process.

| Project facts | |

|---|---|

| Timeline | 2021-2022 |

| Project location | Luxembourg |

| Project type | Construction |

| Machines used | 4 x SC8000 |

| Special extensions used |

|

| Main contractor | Annen plus S.A |