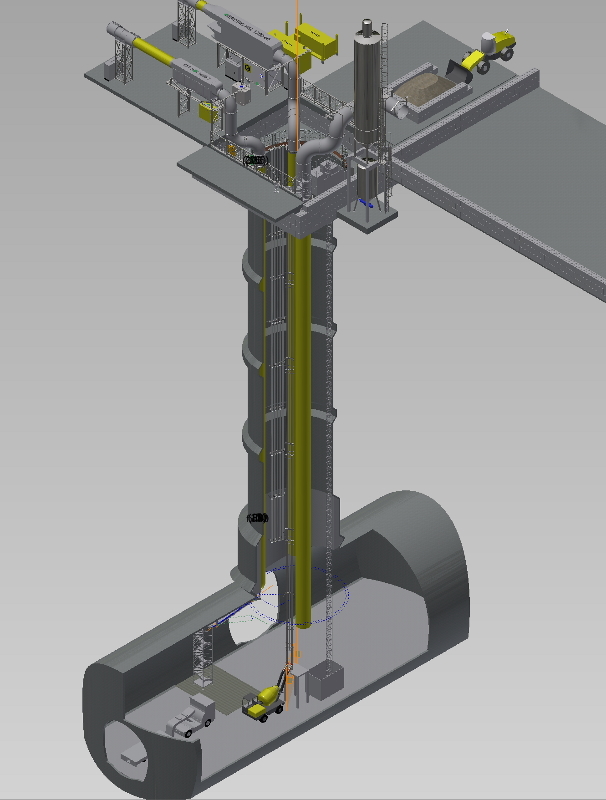

At CERN, Switzerland is the world’s largest and most powerful particle accelerator. It consists of a 27-kilometer ring of superconducting magnets. CERN is currently extending the particle accelerator. This project includes underground excavation works. Point 1, at LHC (Large Hadron Collider), is the underground tunnel access shaft. The access shaft is 71m deep. Scanclimber’s Falcon SC1432F hoist was employed in the access shaft to transport personnel and materials to and from the ground level. After completion of the tunnel, the access shaft shall remain in place. The shaft will be equipped with a staircase and elevator for the particle accelerator’s operating personnel.

Project challenges

The tunnel’s excavation and construction work was carried out around the clock, five days per week. Workers and material needed to be transported through the 71-meter access shaft. The shaft length and traffic volume made this transport process challenging. Before the hoist, the contractor, Marti Tunnel AG, previously had a winch-driven passenger cage to transport workers and materials. However, the capacity of the winch method was limited to only 2-4 persons at a time.

Another challenge was the confined space in the access shaft. The access shaft has a diameter of 12 m, and through this shaft, materials and personnel were to be transported to the tunnel, waste material from the excavations was to be taken out of the tunnel with a gantry crane. The access shaft also has two supply and exhaust air ducts.

Solution

An access shaft of 71m for the transportation of workers and materials.

After consultations and negotiations with Scanclimber in Germany, Marti Tunnel AG decided to employ a 1.4-tonne Falcon SC1432F hoist in the access shaft. The hoist had two landing stations, one on the ground level and one on the bottom.

The Falcon hoist transports personnel and materials to and from the ground level. On average, the hoist makes about 100 trips per day, transporting over 50 workers through the access shaft. The hoist has a payload capacity of 1.4 tonnes and can transport 17 workers at a time. The speed of the hoist has significantly improved productivity at the job site.

Since the access shaft had a confined space, the hoist had to be anchored as close as possible to the shaft. Special anchoring with short anchor tubes was used with a wall plate. The entire access shaft was coated with shotcrete and special dowels for used to drill holes for the anchors to avoid water ingress into the shaft.

The project entailed continuous excavation work and constructing a new floor. The entrance level of the ground station of the hoist had to be constant. For this, a pit was dug in the tunnel. A steel frame was built in it. The ground station was mounted on this steel frame. The access to the hoist was through a staircase built on the steel structure. Thus, regardless of the entrance level of the lift, the complete floor of the shaft base could be removed and rebuilt. After dismantling the hoist, the pit was closed.

Conclusion

Projects like this require careful site planning, discipline, and proper site management. The installation of Scanclimber’s mid-speed/high-speed hoist in the project catalyzed productivity at the job site.

| Project facts | |

|---|---|

| Timeline | July 2019 – July 2020 |

| Project location | CERN, Geneva, Switzerland |

| Working height | 71m |

| Machines used | SC1432F-H48 |

| Number of units | 1 |

| Main contractor | Marti Tunnel AG |

| Project type | Access shaft to an underground tunnel |