A Mast Climbing Work Platform (MCWP) is a type of temporary, powered access equipment designed to lift personnel, tools, and materials to various heights during construction, renovation, and maintenance projects. Unlike traditional scaffolding, Mast climbers offer a vertically moving work deck that provides greater efficiency, higher load capacities, and improved safety for work on building façades or other elevated structures.

Mast climbers are widely used in industries such as construction, façade installation, painting, plastering, glazing, cladding, and inspection. They are valued for their versatility, speed of installation, and ergonomic working conditions compared to scaffolding or boom lifts.

High Load Capacity

Adjustable Height

Faster Installations

Enhanced Safety

Space Efficiency

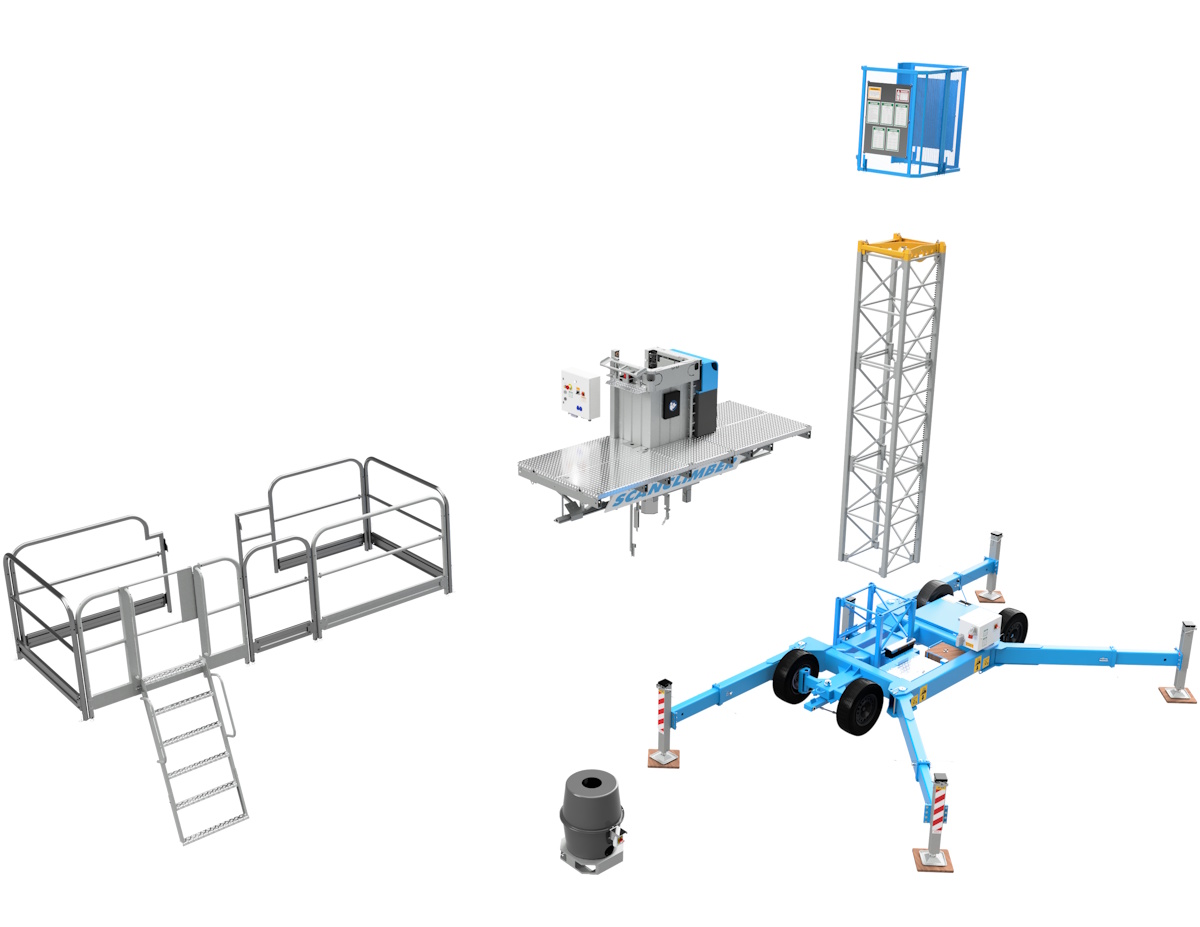

Main Components and Parts of a Mast Climber

A Mast Climber consists of several key components working together to provide a safe and stable work platform. The diagram below highlights the main parts, with detailed descriptions provided for clarity.

How a Mast Climber Works: A Step-by-Step Process

The Mast Climber operates on a rack-and-pinion system, where a motor-driven gear moves along a toothed mast. The process from setup to operation is systematic to ensure stability and safety.

Assembly and Installation

The mast is erected on the base frame (chassis) and anchored securely to the structure at required intervals. The platform is then mounted onto the mast and connected to the drive system.

Operation

Operators stand on the platform and use the control panel to move up or down. The motor turns the pinion gear, which travels along the rack, lifting or lowering the platform with precision.

Anchoring and Stability

At set heights (usually every 3–30 meters), the mast is tied to the building. This critical step prevents lateral movement, sway, or tipping, ensuring the platform's stability at elevation.

Work at Height

The platform can be stopped at any desired height, providing an ergonomic and stable working level for tasks like façade cladding, bricklaying, or window installation, boosting efficiency.

Primary Industry Applications of Mast Climbers

Mast climbing work platforms are versatile tools utilized across various construction and maintenance sectors.

Mast Climber vs. Traditional Scaffolding

When compared to traditional scaffolding, Mast Climber offer significant advantages in efficiency and capacity. This chart compares key performance metrics, demonstrating the productivity gains possible with modern access equipment.

High Load Capacity

Ability to carry heavy materials and workers

Adjustable Working Height

Allows work at optimal ergonomic levels

Faster Installation

Requires less time and labor to set up

Safety

Built-in features enhance worker safety

Benefits of

Mast Climbers

Space Efficiency

Minimal ground footprint keeps site access clear