For the “L’Arc de Triomphe Wrapped” project, the Christo team and Les Charpentiers de Paris chose Scanclimber to design and supply a number of access platforms. These were specially adapted for the installation of the structures that support the covering fabric under the vault of the Arc de Triomphe.

Arc de Triomphe, in full Arc de Triomphe de l’Étoile, is massive triumphal arch in Paris, France, one of the world’s best-known commemorative monuments. The Arc de Triomphe is the symbol of French national identity and took 30 years to build.

Source: Arc de Triomphe | History, Location, & Facts | Britannica.

“L’Arc de Triomphe, Wrapped” was a temporary artwork for Paris designed by world-renowned Christo. It was visible for 16 days from September 18. to October 3., 2021. Christos organization realized the project in partnership with the Centre des Monuments Nationaux and coordination with Paris City. The wrapping of Arc de Triomphe included 25,000 square meters of recyclable fabric in silvery blue and 3,000 meters of red rope, and massive support structure works.

About Christo

In 1961, Christo and Jeanne-Claude began creating works of art in public spaces. One of their projects was to wrap a public building. 1961 Christo rented a small room near the Arc de Triomphe, and the monument attracted him. In 1962, he made a photomontage of the Arc de Triomphe wrapped, seen from the Avenue Foch and, in 1988, a collage. Sixty years later, Christos’s dream was finally concretized.

Some history of the Arc

Arc de Triomphe stands at the centre of the “Place Charles de Gaulle” , the western terminus of the avenue des Champs-Élysées; just over 2 km away, at the eastern terminus, is the Place de la Concorde. Napoleon I commissioned the triumphal arch in 1806—after his great victory at the Battle of Austerlitz (1805)—to celebrate the military achievements of the French armies. The arch, designed by Jean-François-Thérèse Chalgrin, is 50 metres high and 45 metres wide. It sits in a circular plaza from which 12 grand avenues radiate, forming a star, which is why it is also called the Arch of Triumph of the Star.

Construction of the arch began in 1806, on August 15, which was Napoleon’s birthday. The builders completed the foundation in 1810. At the time of Chalgrin’s death in 1811, only a tiny portion of the structure had been completed. Resumption of work was ordered in 1823 by King Louis XVIII. The basic construction of the monument was finished by 1831; contractors completed the job in 1836, during the reign of King Louis-Philippe, who opened it officially on July 29.

Arc was wrapped 2021 for one and half months fully funded by Christo

L’Arc de Triomphe, Wrapped was entirely funded by the Estate of Christo V. Javacheff through the sale of Christo’s preparatory studies, drawings, and collages of the project and scale models, works from the 1950s and 1960s, and original lithographs on other subjects. It received no public funds.

The Centre des Monuments Nationaux, the government institution that manages the Arc de Triomphe, was pleased about realizing a project that demonstrates its commitment to contemporary creation and honors one of the most emblematic monuments in Paris and France.

In front of the Tomb of the Unknown Soldier at the Arc de Triomphe, the Eternal Flame will continue to burn throughout the installation, display, and dismantling of the artwork. As always, veterans’ associations and volunteers committed to the values of the French Republic will ensure the continuity of remembrance and the daily ceremony of rekindling the flame that pays homage to the Unknown Soldier and those who lost their lives fighting for France. The eternal flame and daily rituals at the tomb also challenged the installation project – nobody can distinguish the flame, and ceremonies have to continue.

Christo and Jeanne-Claude have always made clear that their artworks in progress must be continued after their deaths. Christo’s wanted that L’Arc de Triomphe, Wrapped, will be realized by his team.

Arc Wrapping project

The wrapping took place in the following stages:

- Design of the steel support structures.

- Installation of the steel support structures.The steel support structure with wooden padding in many places to maintain Arc untouched and without dents. Installers will tie the canvas and rope to the support structure.

- Wrapping the Arc de Triomphe (attaching the canvas and rolling the 6 km rope around the Arc.

- Unwrapping the Arc.

- Disassembly of the support structure.

Implementation

Christo’s organization chose The Charpentiers of Paris “Les Charpantier De Paris” as the main contractor to install and disassemble the art piece. Mr. Sébastien Roger was in charge of the project. He was the coordinator of all the companies involved: subcontractors, scaffolders, nacelles, all the teams that produce the general schedule of the site.

Mr. Roger said:

It was a massive project for us, an adventure that started again in early 2019 when Christo had contact with us. The Charpentier’s of Paris made with Christo earlier the wrapping project of the Pont-Neuf in 85, and Christo asked us whether we were ready to remake an adventure with him for the packaging of the Arc de Triomphe.

Main contractor – Charpentier’s de Paris

Charpentier’s de Paris was founded in 1893. They specialize in wood frames, metal frame structures, and joinery. Now they employ between 85 and 90 people and master all the projects from beginning to the end: manufacturing, price studies, an internal design office, workshops that allow us to manufacture our wooden structures, our metal or carpentry structures, and afterward, our laying teams that will lay the various elements on the sites.

Sébastien Roger explains the beginning of the project

When Christo came to us in early 2019 to ask us if we wanted to join his project for the Arc de Triomphe, the technical studies were already well advanced on how the project was going to be.

The Charpentiers of Paris began to work together with the German design office SBP. SPB did all the sizing of the structures that have we were supposed to install. Charpentier’s de Paris tried to find the most straightforward solutions to install the structures, which wasn’t easy because of vision differences between designers and those implementing the work.

Arc de Triomphe project installation challenges

Installation of the support frames was challenging in several ways — high arching structures two lower, three higher, reaching up to 28 meters at highest. The eternal flame and the ceremonies had continued under one Arc as always. Men were supposed to work safely on the platform in all circumstances. The Arc formed elements were very heavy, and the walls were inclining inwards.

Mr. Roger explains the challenges.

The real technological challenge was to find the best solution to put the structures in the vaults. The problem with the arches is that we had to place them on cornices. In a metal frame, the simplest is to take the elements and raise them, except that here, being inside the Arc, you could not take the parts and raise them, so you had to take them from below and support them.

If there are accidents on the construction sites, the construction site is stopped, and you cannot go further with the works on the site. At Arc, with the time they were given to do the installation, everything had to be well-planned upfront to minimize the safety problems.

Mr. Roger:

I found the solution of the Scanclimber mast climbing platforms which allowed the elements to be mounted safely. We contacted Scanclimberl. We had meetings on the spot to show them my vision of things, how we were going to be able to assemble the elements, and we worked together to find the best solution to put these structures together.

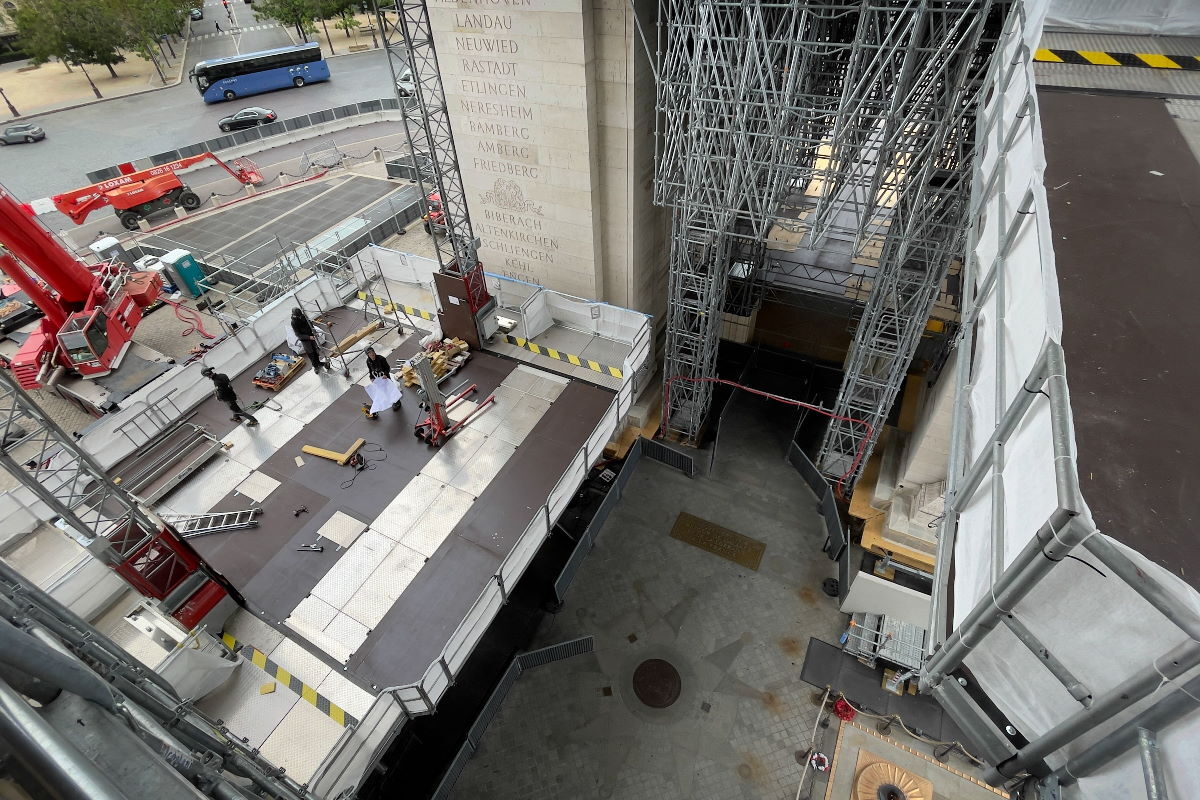

Scanclimber mast climbers allowed them to go all the way to the top of the great vault, which is 22 meters from the ground. These large platforms, which were about 10 meters wide by 12 meters long, allowed them to access the sandbank of the great vault. The two platforms were independent, allowing them to access the sand and put the first elements on the sand. These elements were large metal beams that would enable the distribution of the load of the components that we had to install later.

Mast climbers at Arc de Triomphe

After several conversations with Charpentier of Paris, Scanclimber designed customized mast climbers. Instead of one giant, the final design was two independently moving 10 x 12 meters MCWP:s. Thus it was possible to leave the middle section free for other necessary equipment. Scanclimber designed these SC8000 MCWP:s in the somewhat same vein, as they had created the vast platform at Eiffel tower a few years ago. The platforms had manually moving sliding decks in each corner to enable reach to the Arc every place. These two-mast climbers we only anchored from the top. Each platform with 8. bolts only.

Kevin Ramirez, who from Scanclimber was responsible for the installation of the platforms, commented:

The precautions to prevent any damage to the Arc were so strict that we were not even allowed to drill the anchor bolt holes. I had to be done by Charpantiers de Paris. After we have removed the bolts, an expert company will come in and fill the bolt holes with a specific filling material.

Sébastien Roger from Charpantiers de Pris explained futher:

The complexity of these platforms and of the Arc de Triomphe is that the width at the bottom of the Arc and the width at the top of the Arc are not the same, so we were obliged to design specifically for this project unique moving decks that could glide and widen or shrink the width of the platform. These gliding decks moved inside the structure to allow access to places that one could not have been possible with fixed-width at the platform.

The second phase of the platforms was to carry the enormous load of the entire support structures that they were going to install at the top of the vault, in five arcs, five half circles connected with a beam along the whole length of the vault – 22 meters long – laid on a truss beam that was 32 meters long. They made carriers that allowed Chapantier’s staff to put all that load of 22 tons on the ground, with feet crossing the platform. During the lifting phase that took place late August, the entire structure was docked and premounted on the large truss beam.

Once Charpantiers organization had installed this large and heavy metal structure in the vault, they went down with the truss beam simultaneously with the platforms. Then we used the platforms to finish the installation and put in the last elements: Taking material to 22 meters — or more, up to 24 or 26 meters.

The last part of the final sequence of the installation was to use the platforms to set up the canvases. We placed the canvas under the vault sky, and the canvas was stretched under the vault, hanging on the metal support structures. Once we had tied all the paintings/canvasses in place, the platform was unmounted. In October, when Charpentier de Paris staff came back, Tractel dismantled the platforms.

Why Charpentiers used mast climbers at Arc de Triomphe

Mr. Roger said:

We chose these platforms… after consultations with the Scanclimber teams and with the Scanclimber design unit, to get us the best solution. We needed to load a lot of people — about 20 people on each platform. We came up with this kind of product that could travel with so many people and weight and effectively work at that height. And a minimum anchoring in the Arc de Triomphe was critical. Now we’ve only got an anchoring at the top of the masts.

Charpentier de Paris and Christo Foundation is happy with their decision to take mast climbers into this project. Mr. Sébastien Roger thinks that :

These dual platforms are stable, and they travel fast. And also, he thinks they’re safe in all directions.

He commented:

Sliding decks let us go where we need to. Mast climbers have been capable of taking a load to places where we couldn’t go on a simple scaffold, and they allow us to go down quickly fetch something from ground level. Since all the elements were premounted saved us a lot of installation time. Installing a piece of art like this at Arc in the middle of Paris is a project where you cannot lose a day. If you do, it can have an impact on the finishing date. And that we cannot move. .

Arc de Triomphe installation has been a successful project technically but also from the service perspective.

Sébastien Rogers last comments about the project:

We’ve never had a problem on the platforms, but if we had a problem, there’s a Scanclimber team that’s there, waiting, to intervene and solve the problem. This is the best solution for the project.